Coal presents unique conveying problems as it passes from the mine mouth to the boiler. Its inherent moisture content, combined with the rain, snow and condensation encountered during shipping and storage can cause the coal to instantaneously freeze and bond to the metal surfaces of conveying and handling equipment during winter plant operation. This problem is not unique to coal of course. Sand, cement, powders, recyclables and other industrial materials often encounter the same freezing issues. Fortunately the FRP Heating Panel System is perfectly and specifically suited to handle any material handling equipment winterization application.

FRP HEATING PANEL

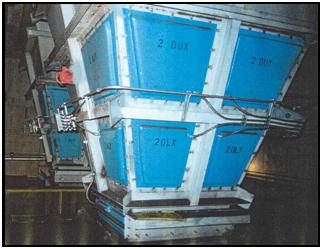

Self-insulated, fiberglass surface heaters to eliminate flash freezing

In any surface heating application, providing maximum heater coverage is the key to success and material handling winterization is no different. Our approach to this unique application is to provide a system of individual, low watt density, custom sized heaters to cover as much of the available surface area as possible. These low watt density heaters keep surfaces above freezing thereby eliminating the flash freezing of coal, sand, soils or other materials to the equipment surfaces. This concept simply cannot be achieved with heating cables, resistance wires or competitive heating module systems that consist of only a small range of fixed size configurations. Nothing outperforms the reliability and suitability of the FRP Heating Panel for this very demanding and difficult surface heating application.

FRP Heating Panels:

- Maximum heater coverage systems; customized heaters to fit virtually any equipment surface

- Low watt density for long life and efficient operation

- Self-insulated heaters, NO ADDITIONAL INSULATION REQUIRED

- Extremely rugged FRP construction to stand up to harsh environments

- Dust tight, vibration proof, COMPLETELY WATERPROOF

- Lightweight, simple to install, remove and reinstall with HTD mounting accessories.

- FM approved for hazardous environments and ordinary areas

Complete systems may consist of heating panels, mounting hardware, thermostats, junction boxes and control/distribution panels. Project engineering will always be provided at no charge and we will make sure all necessary equipment, information and support has been arranged for a complete installation.