HTD Heat Trace hopper heating systems are the most reliable and suitable solution to preventing pluggage and maintaining the free flow of material in collection hoppers. Condensation occurs in collection hoppers when the hot flue gases are allowed to cool to temperatures below the dew point. This condensation conglomerates with the dry, normally smooth−flowing fly ash, or other particulate and quickly turns into a thick, paste-like, immobile mud. The hopper throat area becomes blocked making evacuation of material impossible.

Hopper pluggage and material buildup can lead to:

- Hopper Fires

- Shorting of high voltage buss sections

- Structural damage or complete destruction of the hopper and precipitator or baghouse

- The requirement of plant personnel to manually evacuate the hoppers

HB HEATING MODULE

Specifically designed to maintain elevated surface temperatures on the collection hoppers of

Electrostatic Precipitators, Bag houses, Fabric Filters and other forms of dust collectors

In any surface heating application, providing maximum heater coverage is the key to success and hopper heating is no different. Our approach to maintaining hopper surface temperatures above the dew point is to provide a system of individual, low watt density, custom sized heaters to cover as much of the available surface area as possible. Particular attention and consideration is given in the lower area of the hopper where pluggage is most likely to occur. This concept simply cannot be achieved with heating cables, resistance wires or competitive heating module systems that consist of only a small range of fixed size configurations. Nothing outperforms the reliability and suitability of the HB Heating module for this very demanding and difficult surface heating application.

HB Heating Module Features:

- Flexible/cushioned heater face conforms to hopper irregularities, maintaining intimate heater contact

- Provide maximum heater coverage with sizes customizable from 4” to 18” wide, 6” to 72” long

- Low watt density, uniform heat

- Simple installation with custom cold lead lengths and HTD mounting accessories

- FM and cETL approved

Control & Distribution panels

Mounting hardware and accessories

HB Heating Module Systems can be designed and engineered for any size and number of hoppers; no application is too small or too large. HTD has successfully engineered and supplied thousands of small industrial installations involving just one or two hoppers and a few kilowatts as well as the largest hopper heating installations in the world, involving several hundred individual systems and connected loads up to 4 Megawatts.

Every system is custom engineered to meet the exact needs of each project and the complete hopper heating package may consist of HB Heating Modules, mounting hardware, flexible throat and poke tube heaters, power junction boxes, temperature controllers, control and monitoring panels and power distribution cabinets.

HB Heating Module Systems have been successfully used on thousands of major power and industrial air pollution control projects around the world. Since its introduction in 1976, the HB Heating Module System continues to prove why it is the most effective and reliable solution to hopper pluggage. From its conceptual and physical design to its material and manufacturing quality, there is simply no competitive heater or system that can offer or rival the EFFECTIVE and PROVEN performance of the HB Heating Module and System!

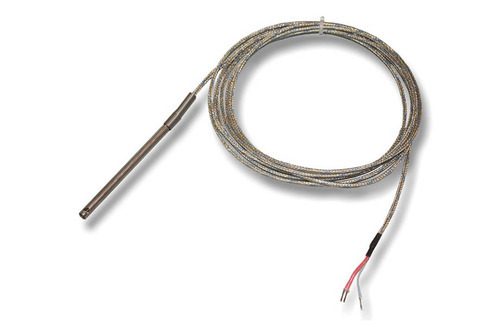

Industrial RTDs and Thermocouples